GTT-Technologies at CALPHAD 2024

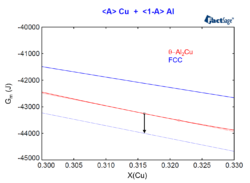

The International Conference on Computer Coupling of Phase Diagrams and Thermochemistry CALPHAD took place from 26 to 31 May in Mannheim, Germany. Of course, we at GTT didn’t want to miss out! GTT-Technologies CEO Moritz to Baben and software expert Florian Tang, together with Bengt Hallstedt from RWTH Aachen University, organised the pre-conference workshop “Software tools […]

GTT-Technologies at CALPHAD 2024 Read More »