An entire kiln in your computer: Optimize your process with KilnSimu!

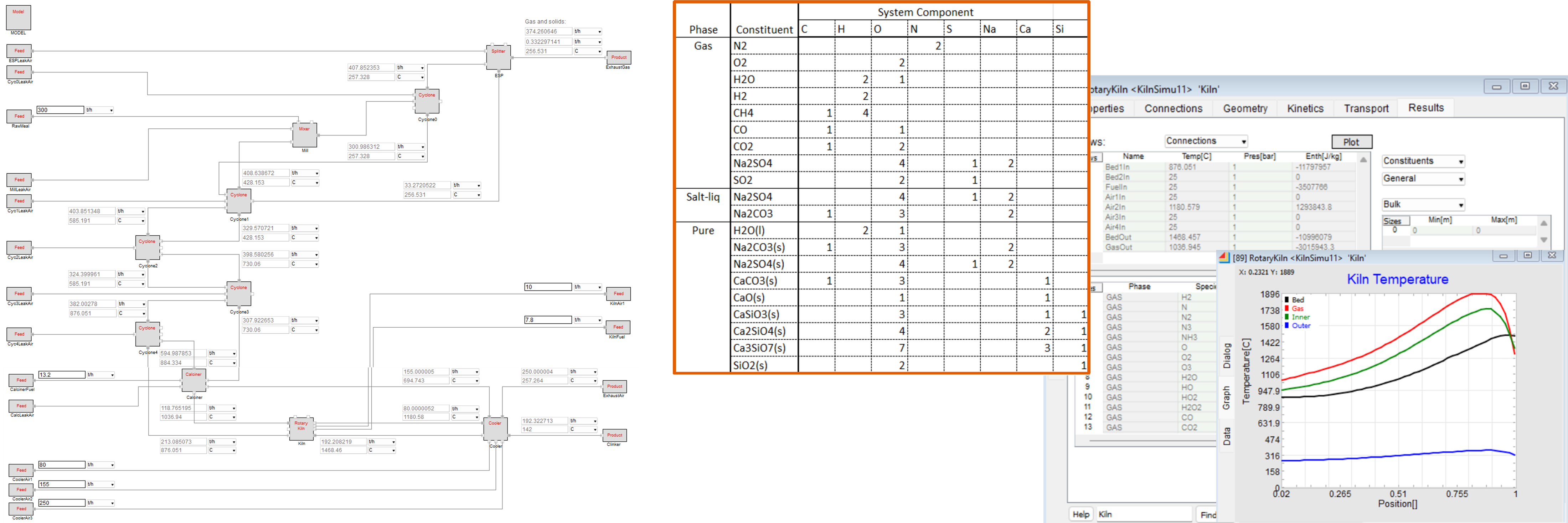

KilnSimu is a powerful rotary kiln simulation software developed jointly by VTT Chemical Technology and GTT-Technologies. It is designed to optimize rotary kiln processes in various industries, providing engineers with the tools needed to increase efficiency, improve productivity, and precisely model thermal processes.

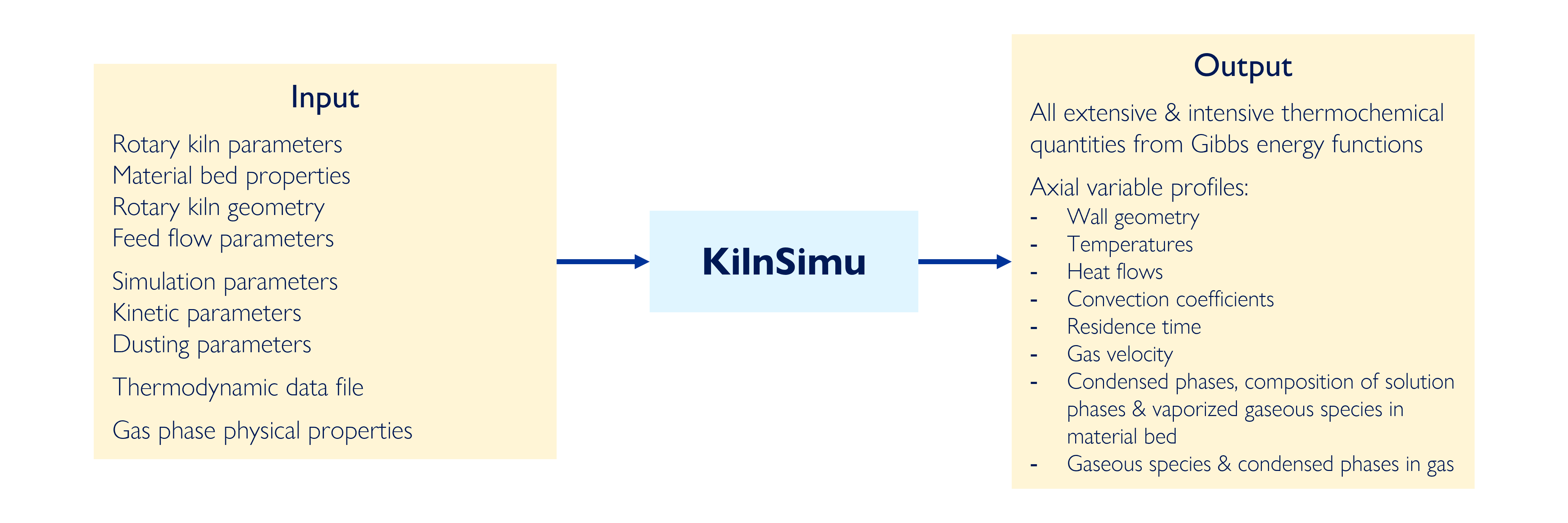

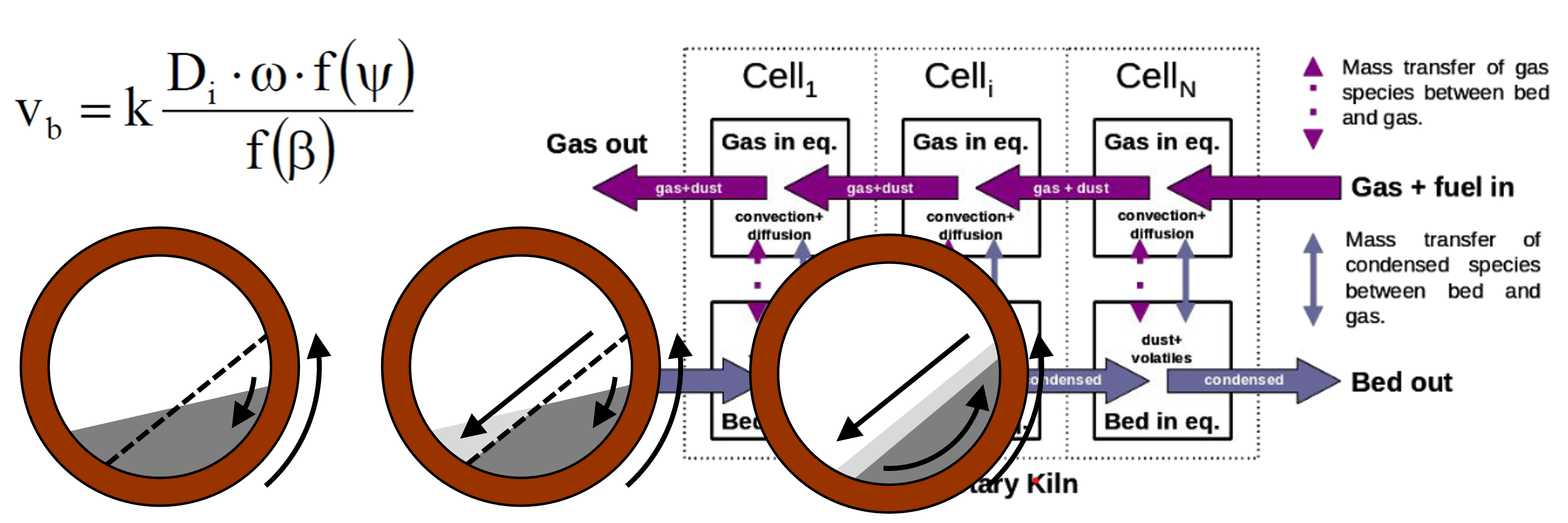

Unlike traditional CFD models that focus on three-dimensional flow dynamics, KilnSimu uses advanced kiln simulation capabilities to provide insight into the chemical composition and phase transformations that occur along the kiln.

By implementing KilnSimu’s rotary kiln simulation software, companies can achieve better operational efficiencies, reduce risks, and address potential issues early in the design phase. KilnSimu empowers engineers to make data-driven decisions by providing deep insight into process interactions and dependencies.

Our thermodynamic expertise tailored for your kiln applications.

KilnSimu combines advanced material modeling with extensive database capabilities to simulate and refine production processes. Whether the focus is on cement production, calcination, reduction processes, or recycling, KilnSimu provides actionable insights that improve productivity, drive cost efficiencies, and foster design innovation.

Enhanced user experience for industry needs

Key features:

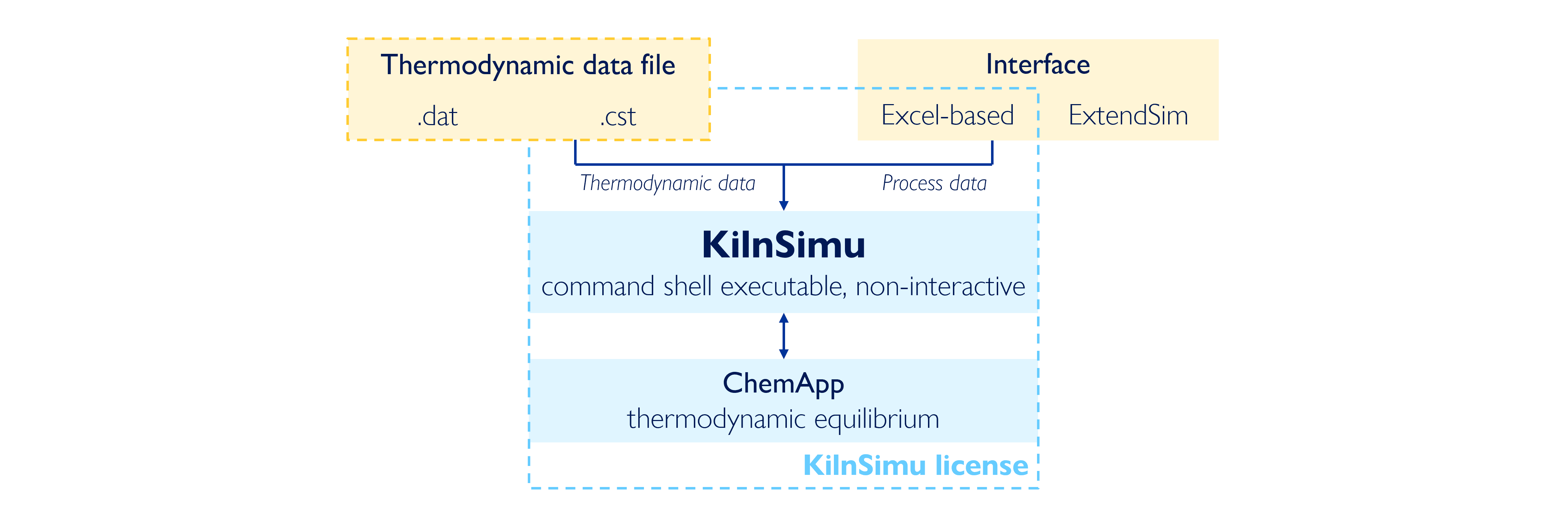

- Flexible licensing, support, and interface options meet industry needs while providing a seamless user experience.

- Intuitive interface for seamless workflow and improved communication across departmentals.

- Rapid evaluation of new materials, fuels, and process configurations.

Bridging simulation and process improvement

Key benefits:

- Supports process knowledge and decision making, pilot plant optimization, and safety and environmental compliance.

- Adapt to changing market or regulatory safety and environmental demands.

- Improve equipment durability and reduce downtime.

- Valuable training and knowledge transfer tool.

Visit the following pages to discover the features, applications, licensing, workflow and documentation of KilnSimu:

OVERVIEW & FEATURES

Explore core features, model inputs and outputs, process units, and training options.

SYSTEM & LICENSING

Understand system requirements, licensing details, and interface options.

APPLICATIONS

Discover application possibilities and industrial solutions that deliver results.

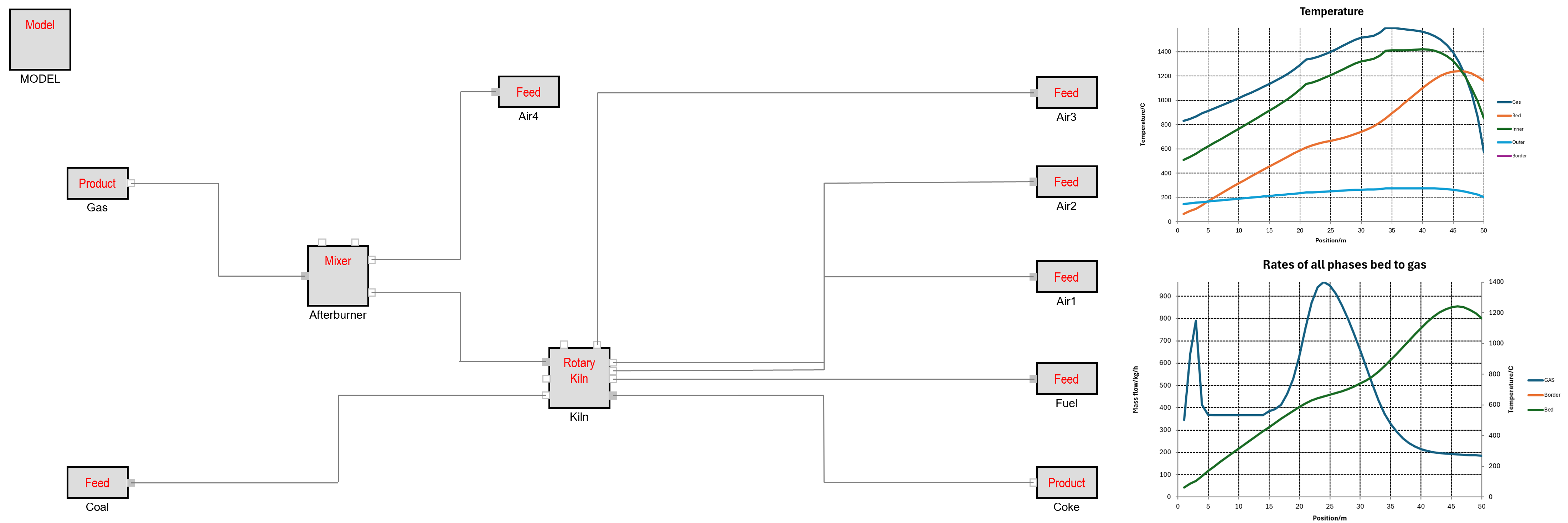

WORKFLOW

Step-by-step cement kiln simulation: See how KilnSimu works.

DOCUMENTATION & BACKGROUND

Access technical details, scientific background, and full documentation.