GTT-TECHNOLOGIES

We help you navigate in chemical space.

NEWS

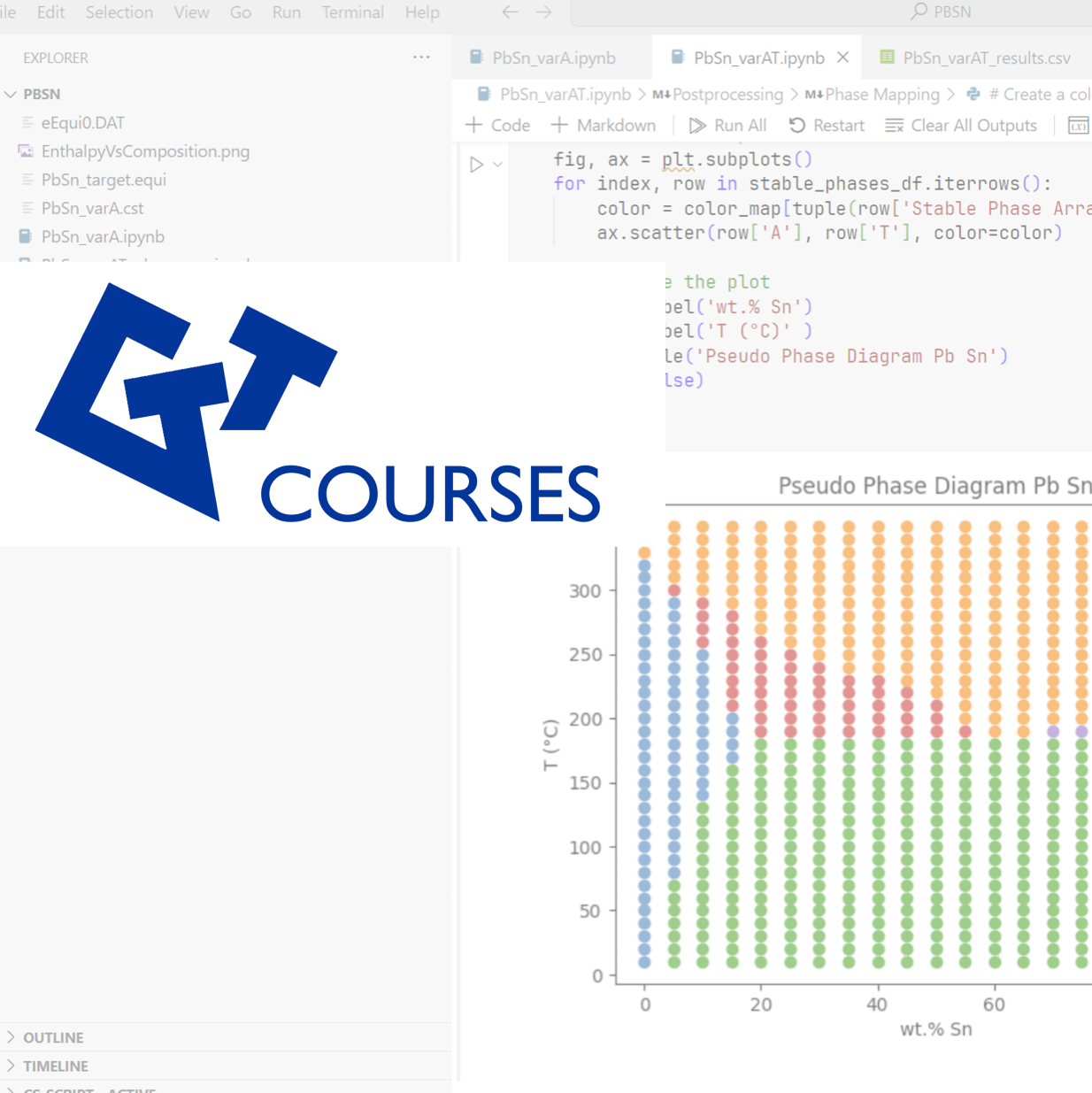

Courses.gtt-technologies.de is online and launches with a self-study ChemApp for Python online course!

Our Users' Meeting is going hybrid in 2024 and will take place from 26 to 28 June in Aachen & online!

We are thrilled to announce the release of our latest FactSage update, version 8.3!

UPCOMING COURSES:

22.-25.04.24: Online training course on FactSage (link)

Self-study online courses: ChemApp for Python (courses.gtt-technologies.de)

THE GTT UNIVERSE

SOFTWARE

Use our software to analyze a wide variety of technical problems - in metallurgy, energy conversion, materials design or materials informatics. Increase your understanding to improve your product and your productivity!

DATA

The principle aim of our thermochemical data supply service is to satisfy our customers' needs for consistent, carefully assessed data of known quality in an easily usable form.